'YED PRIOR': from container ship to gravel hopper dredger

The first contact with Royal Niestern Sander for this special conversion was made by the end of 2019. Mr. D.W. den Herder, owner of Maritiem BV, approached Niestern Sander with a request to make a quotation for the conversion of the Yed Prior, then a container ship called GERD, to a gravel hopper dredger for Spaansen. Originally, Spaansen had nothing to do with shipping, but the company now has its own fleet.

Key figures

22.000 working hours

8 bottom flaps

78 days docked

35 tonnes alignment section

Own fleet for indepence

Spaansen consists of 3 divisions: raw materials and logistics, building systems and garden and paving. Spaansen is great at making prefab concrete parts, such as ready-to-use facades for houses in their hull factory in Harlingen, the Netherlands. In order to meet customer requirements, the company has commissioned its own fleet. The Yed Prior was the last to be added to the fleet. With this, Spaansen is dredging gravel off the coast of Denmark for the concrete precast parts.

Container vessel from Singapore

Spaansen was looking for an existing ship that could be converted into a dredger and that could sail quickly in order to cross the distance Denmark - Harlingen as quickly as possible. That ship was found in Singapore. After a visit and an inspection by D.W. den Herder Maritiem BV the ship was sailed to Harlingen where Bijlsma was commissioned to build new sections for the ship. The hold had to be completely renovated and new foundations had to be placed on deck for the conveyor belts. Bijlsma carried out as many activities as possible while the ship was in the water.

Complex conversion

In the meantime, a shipyard specialized in complex conversions was sought that could put the ship dry. They ended up with Niestern Sander. After Niestern Sander was awarded the job, the ship was put dry on March 18, 2020 and a schedule was made. At the time of the first Covid-19 outbreak, this was a job in itself. The Yed Prior came with a number of defined tasks, such as installing spud-pile lead-throughs, 8 pcs bottom flaps, slide guide, jet water suction, a completely new bow thruster installation, inspection of the rudder, the propeller and propeller shaft. A good example of the close cooperation between Niestern Sander and Wagenborg Nedlift was the installation of a 35T heavy gauge section in front of the suction tube. By means of an SMPT this section was driven to its place with millimeter accuracy in the dock.

Hydrajetting

The ship was also completely stripped of all old paint layers by means of hydrajetting, an operation lasting more than a week in which work continued day and night. The most advanced equipment in Europe was used for this. Work has also been carried out for a large survey.

Unforeseen damages

It soon turned out that there were also a number of unforeseen damages in the skin of the ship and the activities were not agreed upon. In good consultation, the follow-up and the approach were discussed with Spaansen and we came to a plan that both parties could agree with.

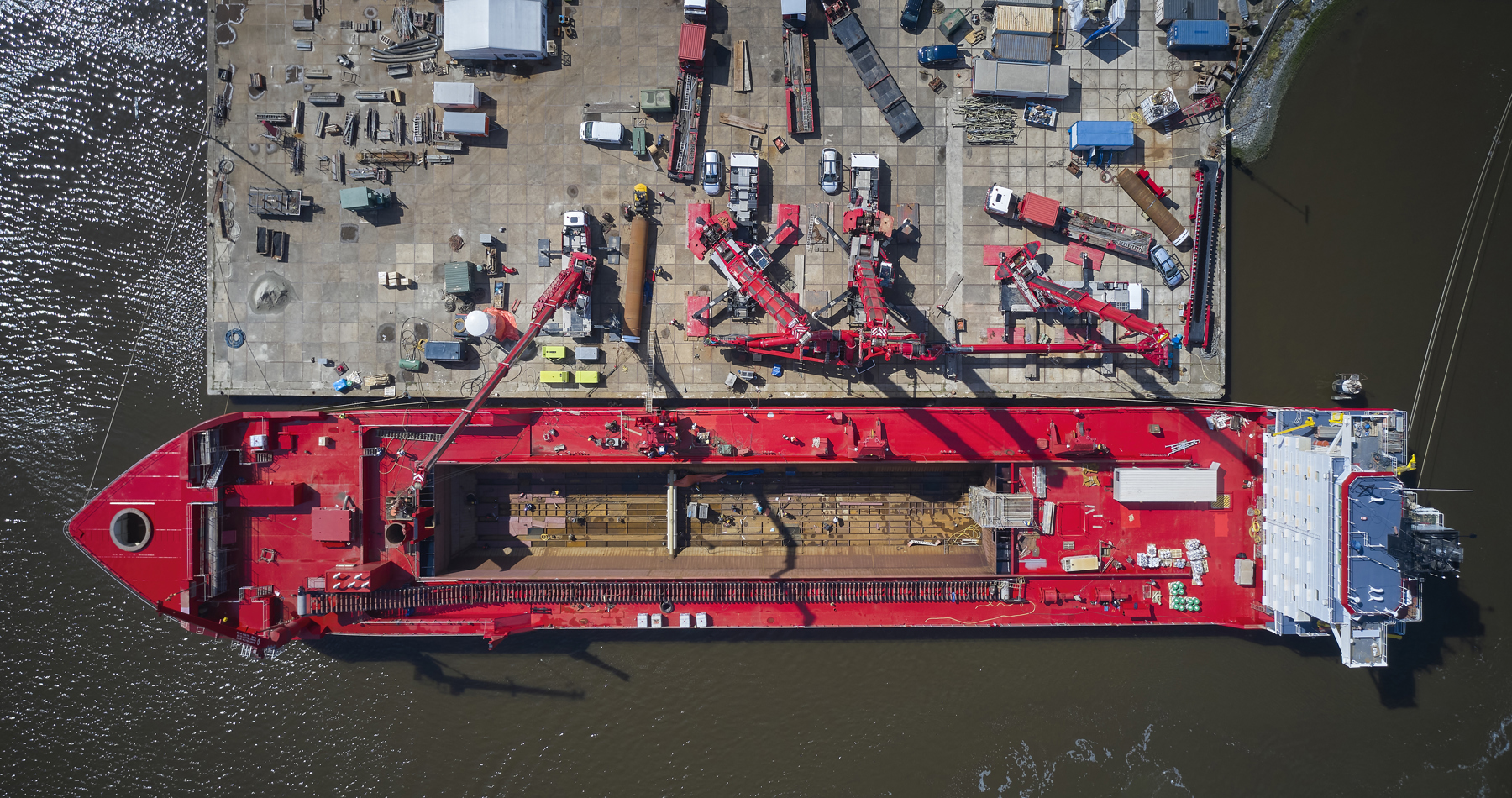

"Spaansen red"

After the ship was completely painted in the characteristic “Spaansen red” colors, it was located at the terminal for a period where further work was carried out, such as the installation of large filter installations and, very special, a conveyor belt on the fore ship that enables the ship to be able to unload its cargo at a distance of about 40 meters from the quay.

In the end, the “Niestern Sander crew” facilitated an additional 100 men who were directly on board by order of the shipowner, and an additional 60 Niestern Sander personnel worked on the Yed Prior. The entire project was completed without further incidents to a beautiful end result.

Test dredging in IJmuiden

Work on the Yed Prior was completed underwater at the beginning of June 2020. The ship then remained at Niestern Sander for other activities until 10 August. On August 10 it was time for the sea trials and on August 16 the Yed Prior, the new dredger of Spaansen, was completely ready. The Yed Prior's first destination was IJmuiden, where she could easily perform test dredging.

In total, Niestern Sander had the Yed Prior in dock for 78 days and put 22,000 hours of craftsmanship into it. Spaansen is happy with the end result and has now put the ship into operation.