Walk to work vessel 'KROONBORG'

Royal Niestern Sander developed Kroonborg, a Walk to Work Service Operation Vessel (SOV) specialized for maintaining offshore wind farms and oil & gas installations. The in-house designed vessel is the result of the knowledge and experiences of the offshore industry and Niestern Sander as a versatile shipyard. The unique ship design completely focusses on workability, comfort and safety and was awarded Ship of the Year.

Key figures

60 POB accommodation

79,42 meters in length

500 m2 uncovered deck space

2,5 meters Hs operability

The new standard in offshore support and maintenance

Royal Niestern Sander developed Kroonborg, a Walk to Work Service Operation Vessel (SOV) specialized for maintaining offshore wind farms and oil & gas installations. The in-house designed vessel is the result of the knowledge and experiences of the offshore industry and Niestern Sander as a versatile shipyard. The unique ship design completely focusses on workability, comfort and safety and was awarded Ship of the Year.

Motion compensated elements

The entire vessel was designed around the motion compensated gangway and crane, resulting in a central position of these functionalities. The Ampelmann gangway was selected as the best suitable ‘walk-to-work system’, in terms of operation speed of the system, simplicity of operation, power consumption and HSEQ, to transfer technicians and cargo safely from the vessel to offshore structures in waves up to 3,0 meters and wind speed up to 20 m/s (38,8 knots). The gangway allows technicians a horizontal ‘walk-to-work’.

The Walk to work vessel is also equipped with a motion compensated crane, which is used to transfer equipment from the vessel onto a platform. The motion compensated T40 Barge Master crane is small and compact. The T40 Barge Master crane is capable of transferring equipment to and from a platform and the deck of the vessel in wave heights up to 3 m.

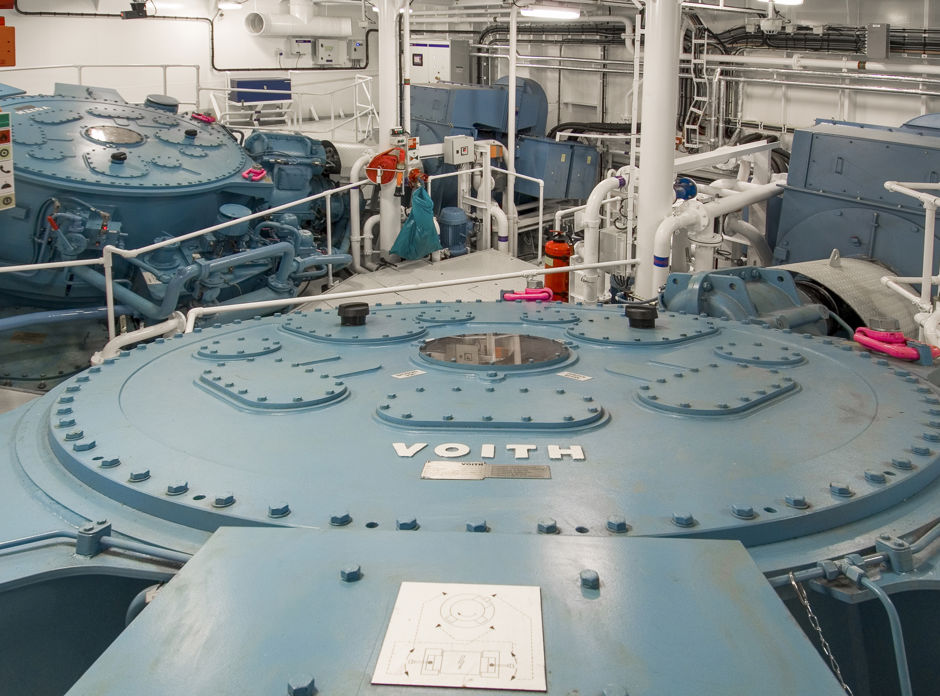

Voith Schneider Propellers

The Walk to Work Service Operation Vessel Kroonborg is equipped with Voith Schneider Propellers (VSP). This type of propulsion enables stepless and extremely fast control of thrust in terms of magnitude and direction. The VSP enhances the dynamic footprint of the vessel resulting in more accurate and efficient dynamic positioning under all environmental conditions. Additional advantages are roll stabilization of the vessel and fuel savings up to 17,5%.

"This vessel is a step changer for the entire offshore industry"

Comfort

The vessel is designed for offshore service technicians who are not used to sailing. The hull shape and roll damping thrusters result in excellent seakeeping behavior and avoid seasickness. Together with comfortable cabins, welfare facilities and good catering a pleasant working and living environment is evident. Sound and noise levels are taken into consideration during DP operations and transfer operations. For instance, the Voith Inline bow thrusters are extremely low-noise, resulting in a COMF-NOISE 2 and COMF-VIB 2 class notation (Bureau Veritas).

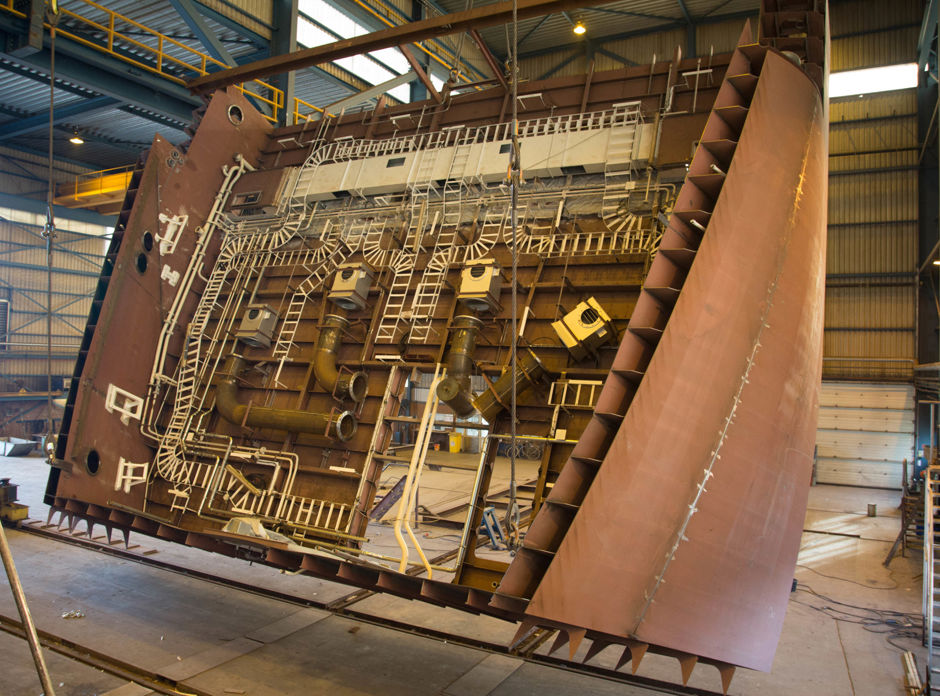

Chemical storage and transport

The Walk to Work Service Operation Vessel Kroonborg was built for operations in the oil and gas industry. Especially for this market, a package of ‘start-up and intervention equipment´ was engineered in the vessels design. With this equipment the vessel can transport all of the chemicals needed for intervention and restart work on a platform. The tank layout includes the below deck storage capacity for these chemicals in duplex steel tanks, in accordance with LHNS requirements and IBC Code for type 2 chemicals. A high pressure pumping system for MEG-injection is installed in a dedicated pump room below deck.

The design of the vessel is unique and complex. We are very proud to build this vessel.

Safety & sustainability

Kroonborg is an accommodation vessel, IMO 2 tanker, workboat and supply vessel in one design and hereby one of a kind. After thorough research and a tight cooperation between ship builder, client, end-user and various suppliers, a concept with many functions was designed, which will change the entire offshore industry. Today, Kroonborg enables offshore operations to be more efficient, safe, comfortable and environmental friendly.